A new technological solution for manufacturing isocyanate-free polyurethane-based coatings for protection against corrosion of various metals

Chemcolor Sevnica d. o. o. is a family-owned developer and manufacturer of coatings for different uses. Part of their successful product portfolio is a special moisture-polyurethane coating with free isocyanates. These coatings are highly adjustable, resistant to chemicals, ultraviolet (UV) and weather, while also characterized with good mechanical properties. Due to these characteristics, the Chemcolor Sevnica d. o. o. can sell these coatings (paints) on a worldwide level.

The company encountered environmental and technological challenge and with the help of the Center for Technology Transfer and Innovation (CTT) at the Jožef Stefan Institute they started cooperation with two technology centers from Slovenia and Hungary. Developed solution was based on the expertise and experience of researchers, while the CTT provided support for financial part of the cooperation.

From Slovenia participated researchers from the Department of Physical and Organic Chemistry at the Jožef Stefan Institute, who are renowned national and international experts for synthesis of new compounds and environmentally friendly coatings. Their theoretical and experimental research activities are focused on physicochemical processes on the solid surfaces (e.g. corrosion). Their expertise aligned very well with the technological challenge of the Chemcolor Sevnica d. o. o.

Synthesis process in the pilot reactor

In cooperation with the researchers the company wanted to develop new technological solution for manufacturing isocyanate-free polyurethane-based coatings, since the polyuretherane technology is one of the most promising systems for coatings and increasing number of final users consider it as the best choice.

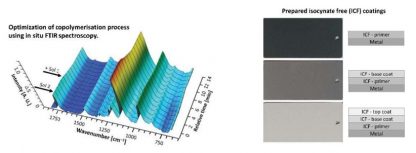

Results

The developed solution resulted in decreased number of side products that have no option of recycling or alternative use (in synthesis), lower total production costs and reduced energy consumption, accompanied with the reduced environment impact.

During the research project the findings confirmed importance of production process optimizations and characterization of coating systems. This resulted in decreased use of hazardous chemicals in the production process and in increased control, but with the less strict conditions. Moreover, the solution is user-friendly, because it doesn’t require so strict procedures as before.

The Slovenian researchers developed in cooperation with the Hungarian researchers from the Bay Zoltán Nonprofit Ltd. for Applied Research a modern solution that brings benefits not only for the company and its production process, but also for final users, leading to a very good example how the technology transfer from research organizations to companies can contribute to progress on several fields in the economy.

Key success factors

As the most influential factors of the project success were identified multidisciplinarity of the methods used and the expertise of both technology centers from Slovenia and Hungary. Special laboratory equipment was used for the analysis of the mechanism of coating formulation, while the techniques of coating characterization allow a thorough insight in the quality of the coating. The quality was also checked according to the standards, since this constitutes basis for verifying the quality of production and the product. The researchers from the Department of Physical and Organic Chemistry obtained new experience, that will impact their forthcoming research activities and cooperation with the companies.

Schematic overview of the process and results

Cooperation took place under the frame of the project KET4CleanProduction, where additional presentation of this succes story is available.

The research project was formed and financed with the support of the Center for Technology Transfer and Innovation at the Jožef Stefan Institute.