How environment friendly aluminium processing and alluminium alloys for application in the aerospace industry were also developed with the expertise of researchers from the Jožef Stefan Institute

FerroČrtalič d. o. o. is a family-owned company with more than 55 years of tradition in the development and manufacturing of machines for surface processing technologies under their registered trademark FerroECOBlast Europe. The company provides the best available solutions to their customers all around the world. Their goals are consultations, presentations of the latest technology solutions, along with the tool and surface processing equipment manufacturing.

The main goal of the cooperation with the researchers was how to find an alternative to the worldwide present challenge of potentially hazardous surface processing based on chemical-based, environment friendly and cost-effective alternative technologies. During the cooperation project the company focused on the development of technologically advanced surface pre-processing in the manufacturing process of aluminium and its alloy and on the development of zirconium-based conversion coating, that is used for improving protection against the corrosion. The developed technology doesn’t require any chemicals and is without any side-products. Used materials can be recycled and returned into the production process once again. As a consequence the health and environment impact is decreased. The developed technology has potential uses in other industries – not only in the aerospace industry – and in processes of other manufacturing companies, resulting in a more competitive technology with a decreased impact on the environment. Due to the increased durability of aluminium, the safety in the aerospace industry will be increased as well.

Results

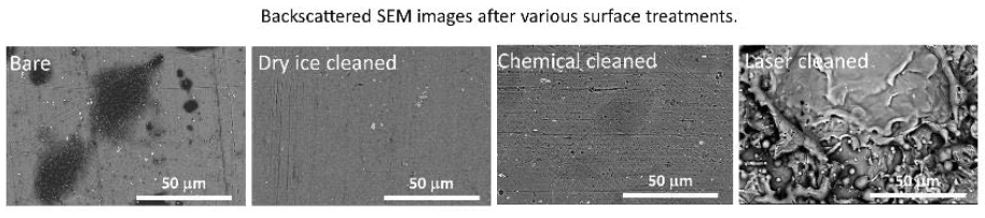

The innovative aspect of the technology solution is in the pre-processing with the dry ice (snow) and shot peening for enhancing the mechanical properties – with the aim to increase the material strength and to prolong the product life – and to gain anti-corrosion protection with the ZrCC. These technologies are not only cost-effective, easy to use and without negative environment impact, but they also reduce the dependence on raw materials. XPS, SEM/EDS and TOF-SIS data obtained between surface characterization before and after different surface processings show the mechanism of the procedure of surface cleaning with the dry ice and formation of ZrCC on the aluminium surface afterwards. Electrochemical measurements enabled characterization and understanding the corrosion process for defining the quality of the surface with or without the pre-processing.

The characterization of the physical and chemical properties of the surface was performed with the assessment of chemical composition, morphology, roughness, micro-hardness and wettability. Tests were performed in the chamber for salt spraying and in compliance with the industrial standards. The results confirmed the maunfacturing quality with the pre-processed and protected surfaces.

Overview of different surface processings under scanning electron microscope (SEM)

Key success factors

The key success factor of the research project was multidisciplinarity of all partners – the company FerroČrtalič d. o. o., the Department of Physical and Organic Chemistry at the Jožef Stefan Institute and Joanneum Research (Austria). All partners have had previous experience in the aerospace industry, especially on the field of surface pre-processing of aluminium alloys. The researchers at the Department of Physical and Organic Chemistry at the Jožef Stefan Institute are in their research activities also focused on physicochemical processes on the surfaces of solids and where central part represent questions connected with the corrosion. Solution of the complex company technology challenge was possible only due to the multidisciplinarity approach and where important role played expertise of researchers from the Jožef Stefan Institute and their previous cooperation with companies, that constituted excellent starting point in finding the answer to the technology challenge.

Systematic and multidisciplinary approach contributed to relevant quantitative and qualitative results about the application possibilities of advanced environment friendly technologies for surface pre-processing and indicated further development of new technology for anti-corrosion protection. Since the company has to maintain its competitiveness and to comply with the environment standards, they have to cooperate with other high-tech laboratories. Therefore, the established cooperation with both technology centers will continue in the future. With this and other forthcoming challenges the support of the Center for Technology Transfer and Innovation at the Jožef Stefan Institute with its network of contacts and connections with other technology centers will play important part in finding new solutions and new partnes. Along with connecting them with researchers at the Jožef Stefan Institute who will be able to provide answers to technology challenges.

Surface processing with the dry ice

Cooperation took place under the frame of the project KET4CleanProduction, where additional presentation of this succes story is available.

The research project was formed and financed with the support of the Center for Technology Transfer and Innovation at the Jožef Stefan Institute.