Alumina Porcelain with Improved Thermal Properties and Procedure of Its Manufacture

| Publication Number: |

SI23000A |

| Application Date: |

30. 3. 2009 |

| Assignee/Applicant: |

ETI Elektroelement d. o. o. [SI], Jožef Stefan Institute [SI] |

| Inventor: |

Marjan Buh, Janez Holc, Marija Kosec, Ivan Lavrač, Martina Oberžan |

| Title: |

Glinični porcelan z izboljšanimi termičnimi lastnostmi in postopek njegove izdelave [SL], Alumina Porcelain with Improved Thermal Properties and Procedure of Its Manufacture [EN] |

| Description: |

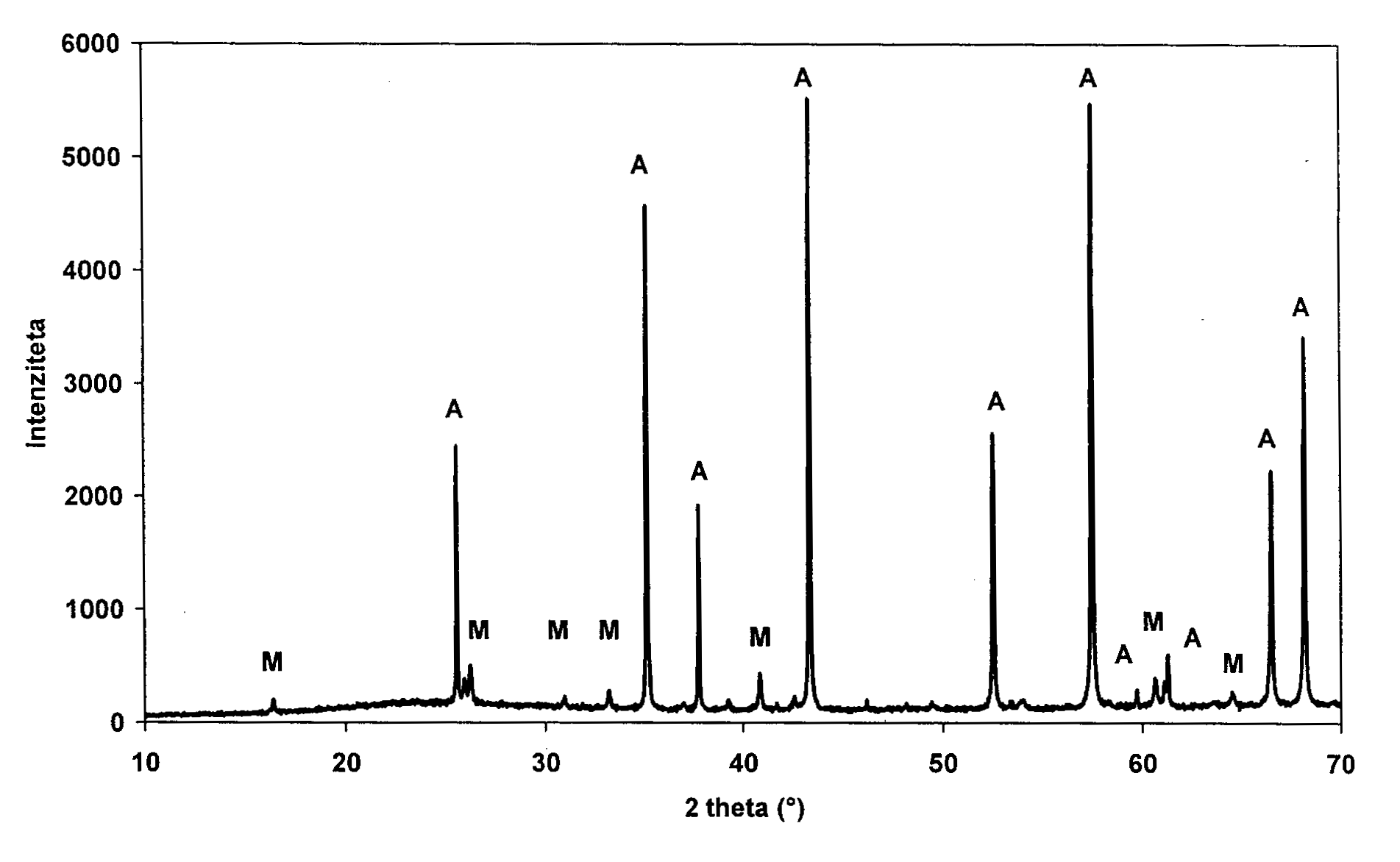

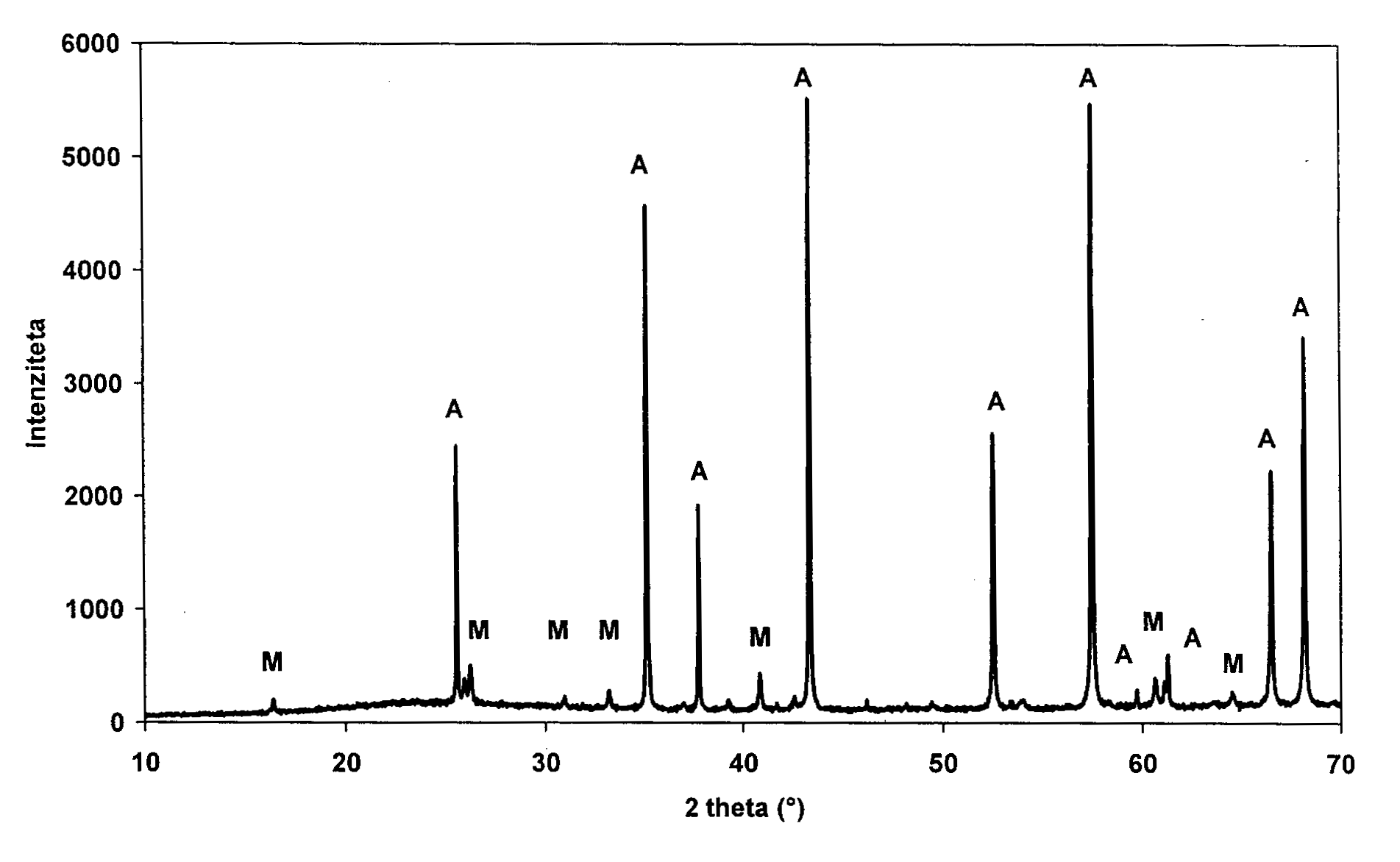

The subject of the invention is alumina porcelain and a procedure of its manufacture. Alumina porcelain according to the invention belongs to the group of alkali alumosilicate porcelains with low thermal dilatation coefficient and contains from 58 to 62 wt.% aluminium oxide, from 0.1 to 0.3 wt.% sodium oxide, from 1.5 to 2.5 wt.% potassium oxide and from 1.0 to 1.4 wt.% lithium oxide. The iron oxide content in the material is less than 0.5 wt.%. After sintering in the temperature range from 1290 to 1330 degrees Celsius, ceramic material is thermally treated at a temperature between 900 and 1050 degrees Celsius in the period of 10 to 240 minutes. Ceramic material with the said composition and sintered and thermally treated according to the procedure described shows a thermal dilatation coefficient from 4.6 to 5.2 x 10 exp6/K within the temperature range from 20 to 600 degrees Celsius, a flexural strength higher than 160 MPa and contains minerals such as corundum, mullite and lithium alumosilicate. |

| Drawings: |

|

| Category: |

Nanotechnology and New Materials |

| Technology application codes: |

Industrial manufacturing, material and transport |

| Market application codes: |

Industrial products, Other |

| www: |

https://worldwide.espacenet.com/patent/search/family/042824911/publication/SI23000A?q=si23000 |

| Patent offices: |

UIL RS |