The Manufacturing Process of Voids in the Ceramic Multi Layered Structures

| Publication Number: |

SI23761A |

| Application Date: |

3. 6. 2011 |

| Assignee/Applicant: |

Center of excellence NAMASTE Ljubljana [SI], Hipot – RR d. o. o., research and development of technologies and systems [SI], Kekon d. o. o. [SI], Jožef Stefan Institute [SI] |

| Inventor: |

Belavič Darko, Holc Janez, Hrovat Marko, Jordan Boris, Kosec Marija, Makarovic Kostja |

| Title: |

Postopek izdelave praznin v keramičnih večplastnih strukturah [SL], The Manufacturing Process of Voids in the Ceramic Multi Layered Structures [EN] |

| Description: |

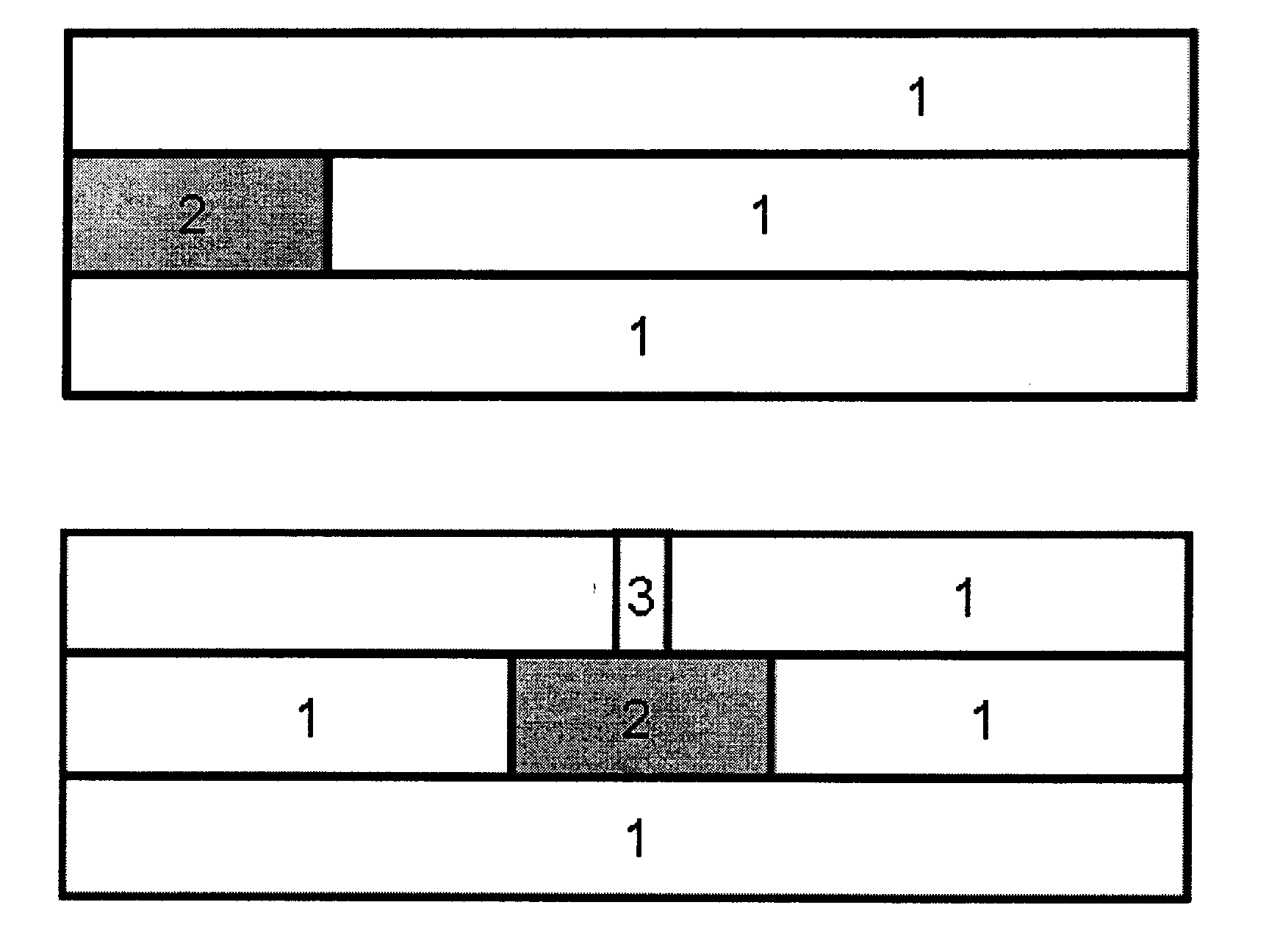

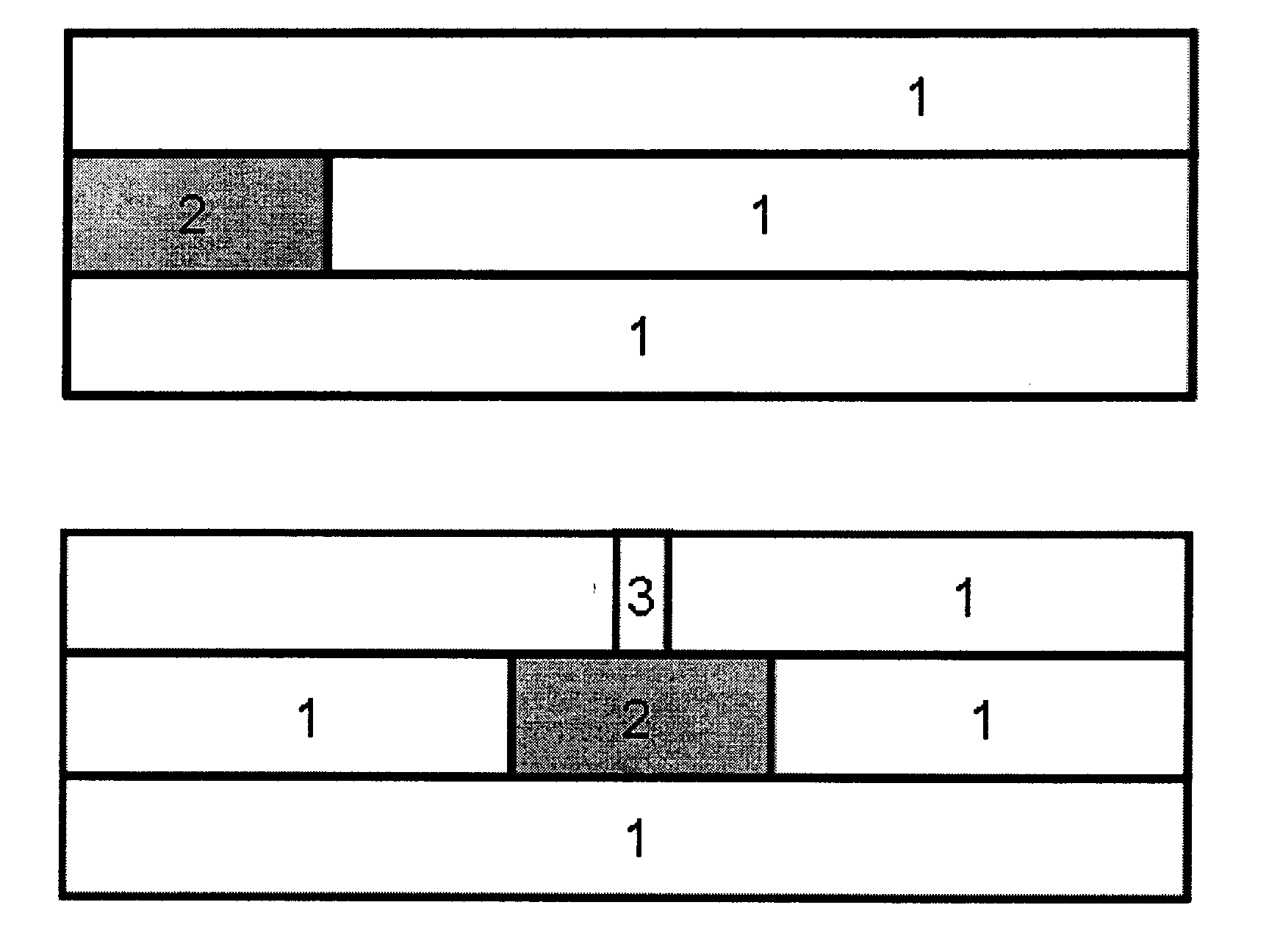

The subject of the invention is a process of making voids in a multilayer ceramic structure by using magnesium carbonate (2) or mixtures of salts of magnesium carbonate and magnesium hydroxide in various proportions as the material in the places where the void will be. Magnesium carbonate (2) is inserted into the multilayer ceramic structure in the form of a paste or foil as an auxiliary material. The place where the magnesium carbonate (2) is located must be open after firing. The ceramic foils are folded in such a way that gaps are obtained in the right places and the whole structure is compressed uniaxially or isostatically. The compressed multilayer ceramic structure is fired at a temperature of 800 to 1400 degrees C for 5 to 240 minutes. After firing, the multilayer ceramic structure is soaked in an aqueous solution of organic acids to remove the fired magnesium carbonate (2). |

| Drawings: |

|

| Category: |

Nanotechnology and New Materials |

| Technology application codes: |

Other industrial technologies |

| Market application codes: |

Industrial products |

| www: |

https://worldwide.espacenet.com/patent/search/family/047427465/publication/SI23761A?q=si23761 |

| Patent offices: |

UIL RS |